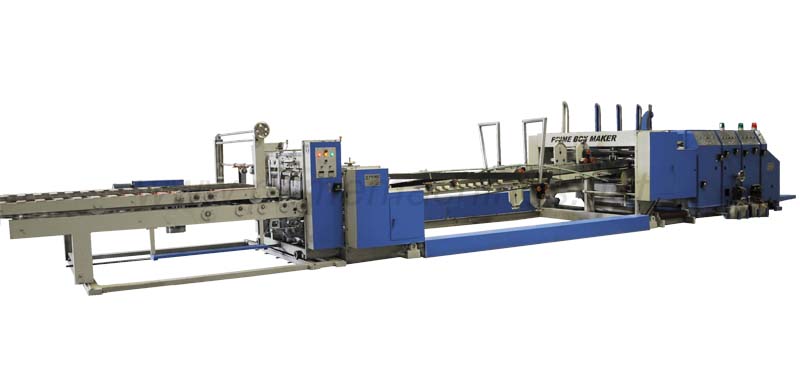

PRIME BOX MAKER

CATEGORY: PREMIUM PLUS

|

|

|

FEATURES

GENERAL

- Machine built on 35mm thickness steel side plates

for smooth running at higher speed.

- All rollers and shafts hard chrome plated.

FEEDING UNIT

- Precise and smooth operation.

- Equipped with vacuum suction kick feeding system,

ensure curved board can be fed smoothly, and also with air adjusting

volume function.

- Heavy duty Cast Steel feeding tracks for

smooth functioning of kick feed system.

PRINTING UNIT

- The Print Units are detachable with motorized

movement.

- Using Bottom printing system to allow Top Fold at

the folder gluer. Top Printing system is also available for printer

slotter machines.

- The print running register is controlled by 360

degree circumferential movement on Push Button.

- Plate mounting system on the print cylinders with

one sided ratchet grip for holding the plate. Plate thickness upto 4mm.

- The Anilox & Rubber roller assembly moves up and

down on pneumatic setting. This helps in quick disengagement of Anilox

roller from the print roller, when the printing is not required. Precise

Anilox and rubber roller with micro adjustment of pressure to ensure good

quality printing.

- Rubber Roller with AUTO IDLE system to prevent ink

from drying on the roller when the machine is stopped.

- The Ink circulation system is automatic for a

consistent viscosity of ink, by using diaphragm air pumps.

CREASER SLOTTER UNIT

- The Upper Slotter roller has a 360 degree

circumferential movement for running register control operated by push

button.

- Unit Movement is motorized.

- 4 sets of Slotting Heads and 4 sets of Creasing

Heads.

- SHIFTING of upper and lower slotting heads along

with creasing heads is done by push button.

- Slot Depth/ Box Height setting on all the slotting

heads is done in a single operation with the help of the adjustment shaft

passing through each slotting head.

- Side Trim/ slot scrap removing belt with inline

folder gluer machine.

FOLDER GLUER COUNTER EJECTOR UNIT

1. With a Unique model of folder gluer, we offer a top folding method

while maintaining the square folded boxes running at variable speeds.

2. Up folding with extended folding length to eliminate fish tailing.

3. Separate operator control station.

4. The movement of FOLDING ARMS is motorized and can be adjusted

according to the size of box to allow a gradual unforced fold.

5. Adapted high friction conveyer belt on upper and lower folding belts.

Press down style through belts.

6. The upper and lower belts work synchronously for correct output

7. Glue application on flap by easy to operate wheel applicator.

8. Top/ Bottom loading squaring hopper ensure accurate bundle count.

9. The box is SQUARED upon coming out from the folding belts and then

counted and ejected in the forms of bundles of required quantity.

10. Available in 2 stage design for smooth operation.

11. Hold Down wheel for bundle compression

12. Counting and feeding out system adopted through high friction belts.

|